Identifying Symptoms of a Blown Head Gasket

If you own a Kohler engine, it is important to know the signs of a blown head gasket. A blown head gasket can cause serious damage to your engine if left untreated. In this section, we will discuss the most common symptoms of a blown head gasket on a Kohler engine.

White Smoke from Exhaust

One of the most noticeable symptoms of a blown head gasket is white smoke coming from the exhaust. This smoke is caused by coolant leaking into the combustion chamber and being burned along with the fuel. If you see white smoke coming from your engine, it is important to have it checked out as soon as possible.

Overheating Engine

Another symptom of a blown head gasket is an overheating engine. When the head gasket fails, it can allow coolant to leak out of the engine. This can cause the engine to overheat, which can lead to serious damage if not addressed promptly.

Rough Idling and Loss of Power

A blown head gasket can also cause your engine to idle roughly or lose power. This is because the head gasket is responsible for sealing the combustion chamber and maintaining the proper compression in the engine. When it fails, it can cause a loss of compression, which can lead to rough idling and a loss of power.

Milky Oil and Oil Contamination

If you notice that your engine oil has a milky appearance or is contaminated with coolant, it may be a sign of a blown head gasket. When the head gasket fails, it can allow coolant to leak into the engine oil, which can cause the oil to become contaminated.

Coolant Leaks

Another symptom of a blown head gasket is coolant leaks. When the head gasket fails, it can allow coolant to leak out of the engine and onto the ground. If you notice coolant leaks under your engine, it is important to have it checked out as soon as possible.

Compression Issues

Finally, a blown head gasket can cause compression issues in your engine. When the head gasket fails, it can allow compression to leak out of the engine, which can cause a loss of power and poor engine performance.

In conclusion, it is important to be aware of the symptoms of a blown head gasket on your Kohler engine. If you notice any of the symptoms listed above, it is important to have your engine checked out by a professional as soon as possible to prevent further damage.

Diagnosing a Blown Head Gasket

If you suspect that your Kohler engine has a blown head gasket, there are a few things you can do to diagnose the problem. In this section, we will cover some of the common symptoms of a blown head gasket and how to diagnose the issue.

Compression Test

One of the most effective ways to diagnose a blown head gasket is to perform a compression test. This test will help you determine if there is a loss of compression in one or more cylinders. To perform a compression test, follow these steps:

- Remove all spark plugs.

- Screw a compression gauge into the first spark plug hole.

- Crank the engine over for a few seconds and take note of the reading on the gauge.

- Repeat this process for each cylinder.

- Compare the readings to the specifications in your Kohler engine manual.

If the compression readings are significantly lower than the specifications, it could be an indication of a blown head gasket.

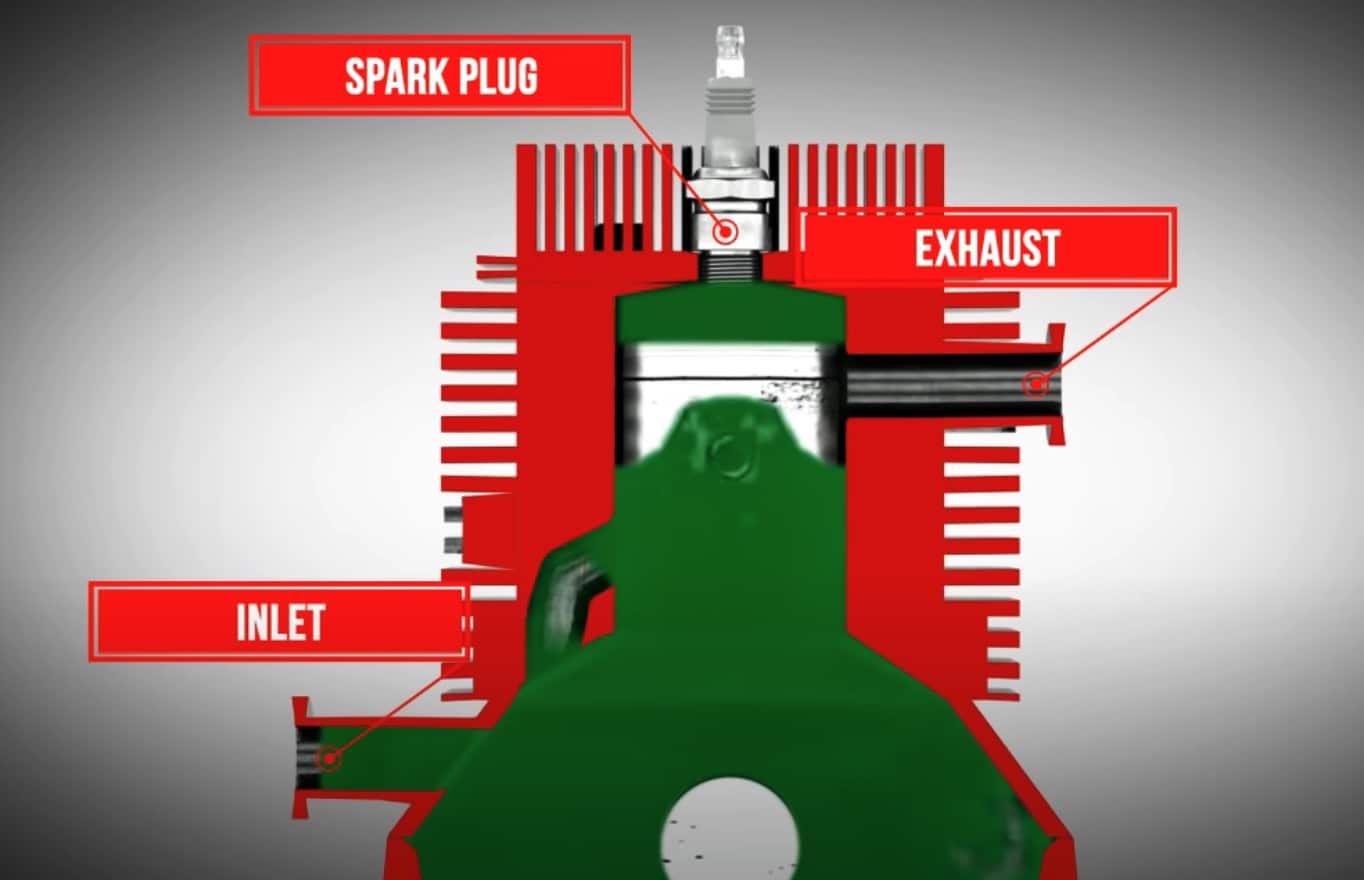

Visual Inspection of Spark Plugs and Coils

Another way to diagnose a blown head gasket is to perform a visual inspection of the spark plugs and coils. If the head gasket is blown, it can cause coolant to leak into the combustion chamber, which can lead to fouled spark plugs and misfiring. To perform a visual inspection, follow these steps:

- Remove the spark plugs.

- Inspect the plugs for signs of coolant or oil fouling.

- Check the coils for signs of damage or cracking.

If you notice any of these signs, it could be an indication of a blown head gasket.

Checking for Oil Leaks

A blown head gasket can also cause oil leaks in your Kohler engine. To check for oil leaks, follow these steps:

- Inspect the engine for signs of oil leaks around the head gasket area.

- Check the oil level and condition. If the oil level is low or the oil is contaminated with coolant, it could be an indication of a blown head gasket.

If you notice any of these signs, it is important to have your Kohler engine inspected by a qualified mechanic to determine the extent of the damage.

In conclusion, diagnosing a blown head gasket on your Kohler engine can be done by performing a compression test, visual inspection of spark plugs and coils, and checking for oil leaks. If you suspect that your engine has a blown head gasket, it is important to have it inspected by a qualified mechanic to prevent further damage.

Understanding the Causes of Head Gasket Failure

If you own a Kohler engine, you may have experienced a blown head gasket. This can be a frustrating and costly problem to deal with, but understanding the causes of head gasket failure can help prevent it from happening again in the future.

Engine Overheating

One of the most common causes of head gasket failure is engine overheating. When the engine gets too hot, the head gasket can warp or crack, causing it to fail. This can be caused by a number of things, including:

- Low coolant levels

- A malfunctioning thermostat

- A clogged radiator

- A damaged water pump

To prevent engine overheating, it’s important to regularly check your coolant levels and make sure your cooling system is working properly.

Pressure in the Combustion Chamber

Another cause of head gasket failure is pressure in the combustion chamber. When there is too much pressure in the combustion chamber, it can cause the head gasket to fail. This can be caused by a number of things, including:

- A damaged piston

- A damaged cylinder head

- A malfunctioning valve

- A clogged air filter

To prevent pressure buildup in the combustion chamber, it’s important to regularly maintain your engine and replace any damaged or worn parts.

Regular Maintenance Neglect

Finally, neglecting regular maintenance can also cause head gasket failure. When you don’t change your oil, replace your air filter, or perform other routine maintenance tasks, it can cause your engine to overheat or build up pressure in the combustion chamber, leading to head gasket failure.

To prevent regular maintenance neglect, it’s important to follow your engine’s maintenance schedule and perform routine maintenance tasks on a regular basis.

By understanding the causes of head gasket failure and taking steps to prevent it from happening, you can keep your Kohler engine running smoothly and avoid costly repairs in the future.

Consequences of a Blown Head Gasket

If you suspect that your Kohler engine has a blown head gasket, it’s important to address the issue as soon as possible. A blown head gasket can cause a variety of problems, including damage to the engine, costly repair and replacement needs, and decreased performance and acceleration.

Damage to the Engine

A blown head gasket can cause serious damage to your Kohler engine. When the head gasket fails, it can allow coolant to leak into the combustion chamber, which can cause the engine to overheat and potentially lead to a cracked engine block. Additionally, if the engine is allowed to overheat for an extended period of time, it can cause damage to the pistons, valves, and other components.

Costly Repair and Replacement Needs

Repairing or replacing a blown head gasket on a Kohler engine can be a costly process. In addition to the cost of the replacement gasket, you may also need to replace other components that were damaged as a result of the failure. If the engine overheated, you may need to replace the engine block or other major components, which can be very expensive.

Decreased Performance and Acceleration

A blown head gasket can also cause decreased performance and acceleration in your Kohler engine. When coolant leaks into the combustion chamber, it can cause the engine to run poorly and potentially misfire. This can lead to decreased power and acceleration, as well as reduced fuel efficiency.

To avoid these consequences, it’s important to address a blown head gasket as soon as possible. If you suspect that your Kohler engine has a blown head gasket, it’s best to have it inspected by a qualified mechanic. They can help you determine the extent of the damage and recommend the best course of action to repair or replace the gasket and any other damaged components.

Preventing Head Gasket Failure

Preventing head gasket failure is crucial to keep your Kohler engine running smoothly and efficiently. Here are some tips to help you prevent head gasket failure:

Regular Maintenance and Service

One of the most important things you can do to prevent head gasket failure is to keep up with regular maintenance and service. Regular maintenance can help identify potential problems before they become major issues. It’s important to follow the manufacturer’s recommended maintenance schedule for your Kohler engine.

Proper Lubrication

Proper lubrication is essential to prevent head gasket failure. Make sure you use the recommended oil and lubricants for your Kohler engine. Using the wrong type of oil or lubricant can cause damage to the engine and lead to head gasket failure.

Timely Oil Changes and Air Filter Replacement

Timely oil changes and air filter replacement are also important to prevent head gasket failure. Over time, oil can become contaminated and lose its ability to lubricate the engine properly. A clogged air filter can also cause the engine to overheat, which can lead to head gasket failure.

To prevent head gasket failure, it’s important to change the oil and air filter according to the manufacturer’s recommended schedule. This will help ensure that your Kohler engine is running smoothly and efficiently.

By following these tips, you can help prevent head gasket failure and keep your Kohler engine running smoothly. Remember to always follow the manufacturer’s recommended maintenance schedule and use the recommended oil and lubricants for your engine.

Professional Repair and Replacement Options

If you suspect that your Kohler engine has a blown head gasket, it is important to consider your repair and replacement options carefully. Here are some options to consider:

Consulting a Professional Mechanic

If you are not experienced in engine repair, it is recommended that you consult a professional mechanic. They will be able to diagnose the problem and recommend the best course of action. A professional mechanic will have the necessary tools and expertise to repair or replace the head gasket properly.

Using Sealants for Minor Leaks

If the leak is small, you may be able to use a sealant to fix the problem. Sealants can be effective for minor leaks, but they are not a permanent solution. If you choose to use a sealant, be sure to follow the manufacturer’s instructions carefully.

Choosing a Reliable Repair Shop

If you decide to have the head gasket replaced, it is important to choose a reliable repair shop. Look for a shop that has experience working on Kohler engines and has a good reputation in the community. Ask for references and read online reviews to ensure that you are choosing a reputable repair shop.

When choosing a repair shop, consider the following factors:

- Experience working on Kohler engines

- Reputation in the community

- Quality of work

- Price

By carefully considering your repair and replacement options, you can ensure that your Kohler engine is repaired properly and runs smoothly for years to come.

Frequently Asked Questions

What are the signs of a blown head gasket on a Kohler engine?

A blown head gasket on a Kohler engine can be indicated by several signs. Some of these signs include:

- White smoke coming out of the exhaust pipe

- Engine overheating

- Loss of engine power

- Milky oil or coolant

- Bubbles in the radiator or coolant overflow tank

If you notice any of these signs, it is recommended to have your Kohler engine inspected by a professional mechanic.

How can I tell if my Kohler Courage 20 needs a head gasket replacement?

If you have a Kohler Courage 20 engine, some of the signs that indicate a blown head gasket include:

- White smoke coming out of the exhaust pipe

- Engine overheating

- Loss of engine power

- Milky oil or coolant

- Bubbles in the radiator or coolant overflow tank

If you notice any of these signs, it is recommended to have your Kohler Courage 20 engine inspected by a professional mechanic.

What are the symptoms of a blown head gasket on a Kohler Courage 19?

If you have a Kohler Courage 19 engine, some of the signs that indicate a blown head gasket include:

- White smoke coming out of the exhaust pipe

- Engine overheating

- Loss of engine power

- Milky oil or coolant

- Bubbles in the radiator or coolant overflow tank

If you notice any of these signs, it is recommended to have your Kohler Courage 19 engine inspected by a professional mechanic.

What are the steps to replace a Kohler KT725 head gasket?

Replacing a Kohler KT725 head gasket involves several steps. Here are some of the basic steps involved:

- Drain the oil and coolant from the engine.

- Remove the air cleaner assembly and carburetor.

- Remove the valve cover and rocker arm assembly.

- Remove the cylinder head bolts and lift off the cylinder head.

- Clean the cylinder head and engine block surfaces.

- Install the new head gasket and cylinder head.

- Torque the cylinder head bolts to the manufacturer’s specifications.

- Reinstall the valve cover, rocker arm assembly, carburetor, and air cleaner assembly.

- Refill the engine with oil and coolant.

It is recommended to consult the Kohler engine manual for specific instructions and torque specifications.

How do I know if my Kohler Command engine has a blown head gasket?

If you have a Kohler Command engine, some of the signs that indicate a blown head gasket include:

- White smoke coming out of the exhaust pipe

- Engine overheating

- Loss of engine power

- Milky oil or coolant

- Bubbles in the radiator or coolant overflow tank

If you notice any of these signs, it is recommended to have your Kohler Command engine inspected by a professional mechanic.

What are the signs of a blown head gasket on a Kohler 7000 Series engine?

If you have a Kohler 7000 Series engine, some of the signs that indicate a blown head gasket include:

- White smoke coming out of the exhaust pipe

- Engine overheating

- Loss of engine power

- Milky oil or coolant

- Bubbles in the radiator or coolant overflow tank

If you notice any of these signs, it is recommended to have your Kohler 7000 Series engine inspected by a professional mechanic.